We personalize your experience.

We use cookies in our website to ensure we give you the best experience, get to know our users and deliver better marketing. For this purpose, we may share the information collected with third parties. By clicking “Allow cookies” you give us your consent to use all cookies. If you prefer to manage your cookies click on the “Manage cookies” link below.

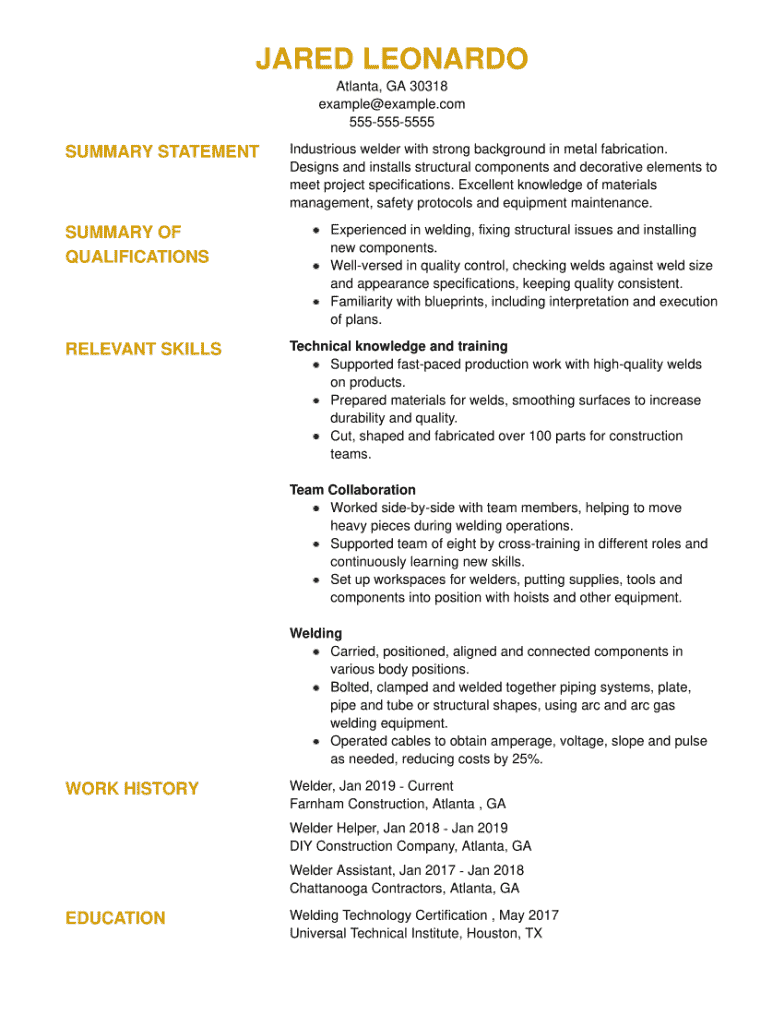

Convince hiring managers you’re the right welder for the job following the welder resume samples and tips in this article.

Our customers have been hired by*:*Foot Note

Welders play a huge role in the manufacturing industry. Whether constructing bridges and buildings or putting their skills to the test repairing aerospace equipment, we’ll teach you how to highlight your accomplishments and skills in an eye-catching way. Or, you can make the welder resume sample below yours in our Resume Builder in just a few clicks.

Make sure your merchandiser resume hits all the right notes following these tips:

Instead of submitting a generic welder resume to the job application, tailor your resume to the welder job description. How do you make a tailored resume? Easy! Choose keywords from the job ad, such as skills listed in the requirements or responsibilities, and include them in your resume as you discuss what you can and have done. Including keywords will also help you make it through the applicant tracking systems (ATS) most employers use to filter resumes.

A great way to impress employers is to highlight important projects or accomplishments in your welder resume. Instead of talking about daily tasks and mundane responsibilities that most welders have, feature projects you were a part of and big accomplishments so hiring managers know that you’re just talking the talk but walking the walk.

As a welder, you need to have an array of hard skills under your belt to do your job, whether it’s technical knowledge or the ability to operate various tools and equipment. That being said, soft skills like communication, attention to detail and problem-solving skills are just as important to assure prospective employers you’re a well-rounded professional.

Many welders receive formal training through vocational schools, technical colleges or community colleges. While obtaining additional training or certifications is unnecessary, pursuing a certification from recognized organizations like the American Welding Society (AWS) can be a great way to enhance your expertise.

When describing your welding experience and skills on your resume, it’s essential to use strong and action-oriented words to highlight your capabilities better. Here are some action verbs you can consider:

For a more detailed list, check our action words article.

Build my resumeOrganize the layout of your resume following one of these three resume formats:

Read the welder job description well to see what hard skills and soft skills the employer is looking for in a candidate. Here are some relevant welding skills you might want to consider:

Write your full name, phone number and email address in the resume header. If you have a LinkedIn profile with additional professional information, you can add the handle as well.

Now it’s time to write the resume summary or resume objective.

A resume summary is a brief overview of your top strengths and qualifications. Typically two to three sentences long, the summary is ideal for welders who have been in the industry for over three years. Here’s what a professional welder resume summary should look like:

A resume objective is similar to a summary but also discusses your employment goals. It should list your top skills and qualifications, as well as the type of job or environment you’re seeking. Take a look at this welder resume objective:

While soft skills count, hard skills are key for a welding career. Therefore, make sure you highlight relevant technical skills in your skills section. List only 8-10 skills, always making sure they’re relevant to the job opening.

When you mention your work history and years of experience, start with your most recent job, then list the one before it and so on. Include dates and company names, and list three to five key accomplishments. Don’t include more than 10 years of experience in this section, unless the welder job description specifically states they want to see your whole professional trajectory.

When possible, include metrics and numbers to portray your accomplishments better.

Highlight relevant training, certifications and any formal education you received to become a welder. Take a look at this welder resume education section:

For more resume-writing tips, check our How to Make a Resume article.

Have questions? We’re here to help.

Here’s how to create a job-winning welder resume:

The specific achievements you highlight on your structural welder resume should be tailored to the company and job you’re applying for. Overall, you’ll want to emphasize project completion efficiency (e.g. “Led welding team, resulting in a 20% reduction in project completion time through improved workflow management and process optimization.”), talk about client satisfaction, equipment maintenance and other special projects that showcase how you’ve used your skills.

An entry-level welder should write a resume objective or objective statement where they include their top skills and training, and express their career goals with enthusiasm. Take a look at this entry-level welding resume summary:

Dedicated and detail-oriented individual eager to launch a career as a welder. A recent graduate with a solid foundation in welding techniques gained through coursework and hands-on training. Possesses a strong work ethic, excellent teamwork skills and a commitment to safety protocols. Aiming to apply my knowledge, learn from experienced professionals and contribute to a dynamic welding team at [Company Name].

Motivated and detail-oriented professional seeking an entry-level welding position to leverage a solid foundation in welding techniques acquired through formal education and hands-on training. Adept at interpreting blueprints, preparing materials and operating welding equipment. Eager to apply theoretical knowledge in a practical setting, contribute to project success, and learn from experienced professionals at [Company Name].

This resume objective:

Each time you apply for a new job, you need to submit a cover letter as well as a perfect resume. This also applies to your welder job application. If you need help with a cover letter, then you can always use a cover letter builder.

If you don’t have a lot of experience in this field and you are applying for an entry-level position, then don’t start listing jobs that are not relevant to this position just to fill out the space. Instead, think about what else you can include in your resume. For example, do you have specialized skills you can add? Have you had volunteer welderwork experience where you developed welding skills relevant to this job position? Did you learn welding processes or welding techniques in high school or college? If so, then mention those in your resume.

Reading the job description carefully is half of the job. In the job posting, you can find relevant keywords related to skills and qualifications you can use in your resume to increase your chances of landing an interview. Using keywords to describe your skills and work experience will help your resume to stand out to the hiring manager.

Couldn't find the answer you're looking for?